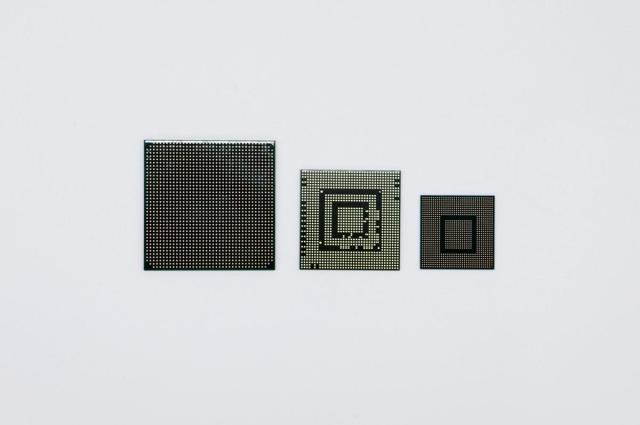

Semiconductor substrates are essential for mounting components on the mainboards of IT devices, facilitating smooth electrical connections, efficient power delivery, and effective heat dissipation for optimal performance and reliable data transfer.

Samsung Electro-Mechanics said Wednesday that its Vietnamese plant in Thai Nguyen recently started production of semiconductor substrates called "Flip Chip Ball Grid Array (FC-BGA)." FC-BGA is a high-density package substrate that connects semiconductor chips and mainboards with flip chip bumps, mainly applied to high-performance computing (HPC) semiconductors due to its fast information processing speed.

According to the electronic component maker, its Viet Nam factory primarily produces AI semiconductor substrates for IT products such as laptops and smartphones, but there is also a possibility of producing substrates for servers, networks, and vehicle electronic devices. Since 2021, the company has invested over 1 trillion won ($719.8 million) in the factory.

LG Innotek has also ventured into the AI semiconductor substrate market by starting mass production of FC-BGA in February. Its FC-BGA products, manufactured in Korea's southern industrial city of Gumi, are currently undergoing quality tests for IT applications.

The two Korean firms are expected to compete against semiconductor substrate producers in Japan and Taiwan. The FC-BGA market is currently led by Japanese companies such as Ibiden and Shinko Electric Industries, as well as Taiwan's Unimicron. As of 2022, Japanese and Taiwanese firms accounted for 69 percent of the global market share by sales, while Korean companies were at around 10 percent.

Data released by the Fuji Chimera Research Institute showed that the global FC-BGA market size is expected to more than double to $16.4 billion by 2030 from $8 billion in 2022.

Copyright ⓒ Aju Press All rights reserved.

View more comments