Copper foils are used in high-performance batteries as current collectors and coatings for electrodes. The key part of a battery cell requires a delicate processing technique to flatten raw copper material into about 20 micrometers, thinner than the average diameter of a human hair. Copper is an abundant metal that is commonly found around the world.

However, the prices of copper can fluctuate based on market demand. Due to the increased demand for electric vehicle (EV) batteries and other high-performance batteries used for renewable energy generation, the international demand for copper has increased during the last decade. The average annual global demand for copper between 2019 and 2022 was about 24.9 million metric tons with an annual average increase rate of about seven percent, according to global market analyst firm Statista.

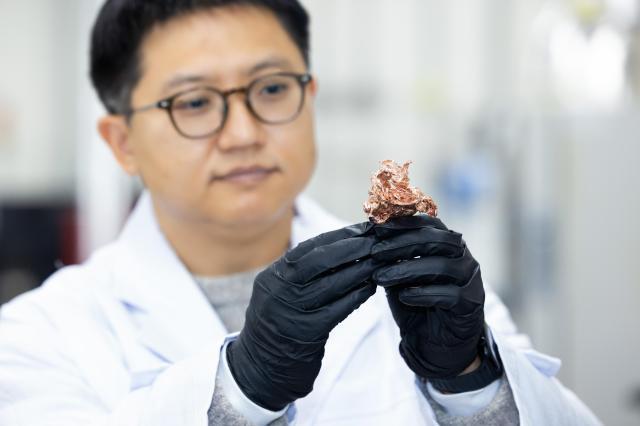

LS Cable said that the company developed a new copper foil material based on copper flakes. The company predicts that the foil material will be commercialized very soon. "We have recently finished sample tests with foil makers. We can start the commercialization process as early as 2024 and we hope to achieve annual sales of more than 10 billion won ($76.9 billion)," an LS Cable official said in a statement on December 20.

According to the South Korean cable maker, the new material requires fewer processing steps compared to conventional copper wire-based material processing, allowing operators to save costs because the flake-based foil material can be created using scrap copper. While the conventional process requires a series of cleaning of base materials, the new process melts base materials to simplify the production process.

Copyright ⓒ Aju Press All rights reserved.

View more comments