[Courtesy of UNIST]

3D printing uses special filaments that are molten before they are sprayed layer over layer to create the final shape. The filaments can be made of different materials that will harden when cooled. Thanks to 3D printers' ability to use different filaments simultaneously, special printing methods are now used in countless industries including the food processing, semiconductor manufacturing, and construction industries.

To actualize virtual reality (VR) or augmented reality (AR), head-mounted-display (HMD)-type headsets are most widely used. However, such devices are bulky and very expensive for ordinary consumers. Smart contact lenses are almost as light as a feather and do not restrict body movements. Also, they can be distributed at affordable prices when they are mass-produced.

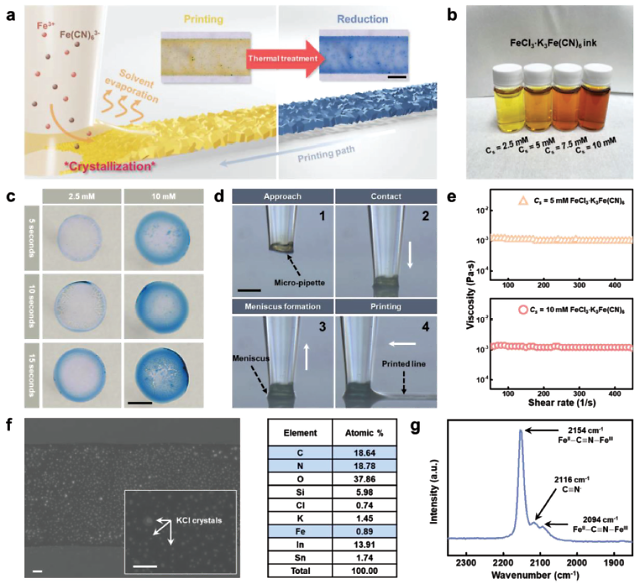

The Ulsan National Institute of Science and Technology (UNIST) said that researchers from the institute and the Korea Electrotechnology Research Institute (KERI) cooperated to develop a 3D-printed smart lens for VR and AR. The lens uses electrochromic display technology to be operated at a very low-voltage level. The high-definition 3D-printing technique was used to print micro-patterns onto the lens' display. Prussian blue, a dark blue pigment produced by the oxidation of ferrous ferrocyanide salts, was used as the material for patterns.

According to UNIST, the smart lens is expected to be widely used in the navigation sector. Using the electrochromic display, the lens was able to show its wearer an AR-based navigation map. "We expect this research will receive a lot of attention from battery and biosensor companies which need Prussian blue-based micropatterning technique as well as companies from the AR industry," UNIST researcher Jeong Im-doo said in a statement on February 6.

Copyright ⓒ Aju Press All rights reserved.

View more comments