[Courtesy of the Korea Institute of Geoscience and Mineral Resources ]

SEOUL -- South Korean researchers have developed a method to recover 98.3 percent of plastic by recycling waste coffee capsules with low recycling rates. Recycled plastic can be applied to various products by efficiently removing aluminum.

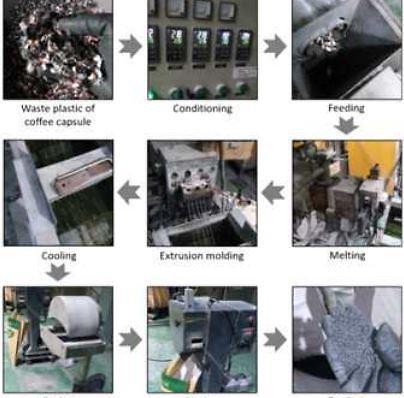

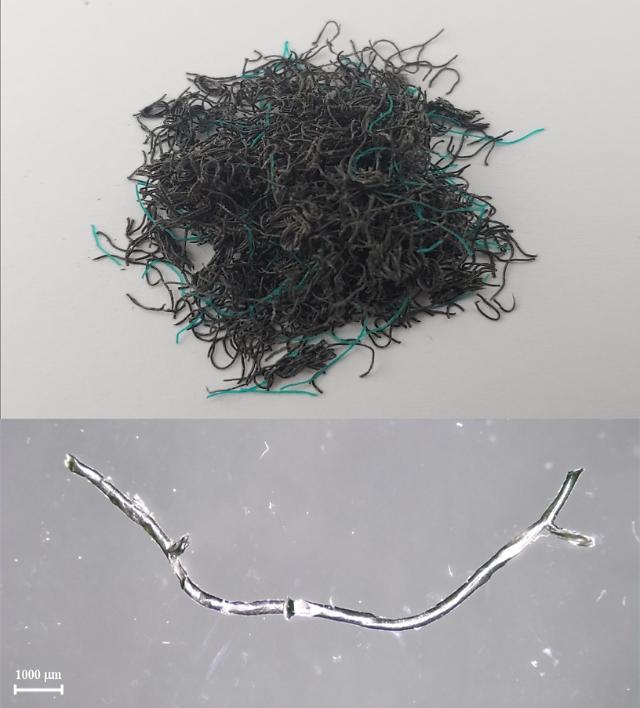

The waste coffee capsule consists of plastic accounts for 97.3 percent of the waste coffee capsule and aluminum 2.7 percent. The Korea Institute of Geoscience and Mineral Resources (KIGAM) said its research team shredded waste capsules and washed them to remove coffee residue. After a cut crusher was used for second crushing to a size of 10mm, aluminum was separated through corona-discharge electrostatic separation.

Electroseparation methods are based on electrophoresis or dielectrophoresis processes involving charged and uncharged particles. The corona-discharge electrostatic separation method uses the electrical properties of particles.

Researchers recovered 98.3 percent of plastic to manufacture pellets that contained no harmful substances in the analysis of physical properties, the institute said, adding that recycled plastic can be used as regenerated propylene because it has similar properties to homopolymer polypropylene, a type of polymer compound mainly useful in packaging, textiles, healthcare, pipes, automotive, and electrical applications.

"I hope this study will serve as an opportunity to create the positive perception of recycling eco-friendly resources that reduce waste and prevent environmental pollution by recycling capsule coffee, which is closely used in real life," Jeon Ho-seok, a KIGAM researcher of mineral resources engineering, said in a statement on October 26.

In August 2022, GS Caltex, a major refiner in South Korea, partnered with Swiss multinational food and drink giant Nestle to create eco-friendly composite resins by upcycling coffee capsules.

I

Copyright ⓒ Aju Press All rights reserved.

View more comments