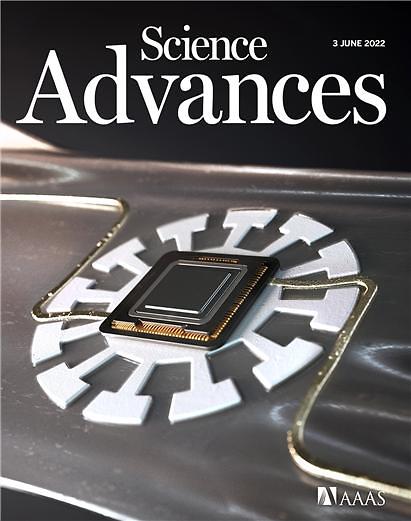

[Courtesy of KAIST]

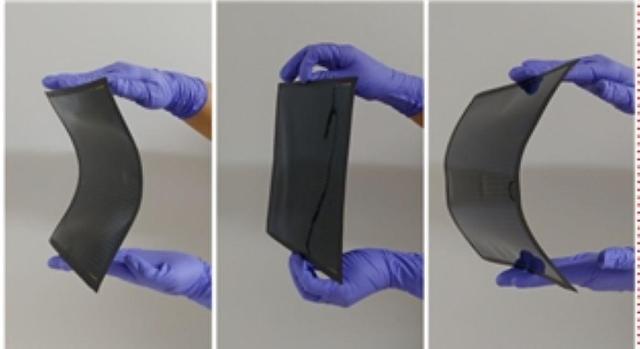

SEOUL --South Korean researchers have developed a Ferris wheel-shaped polymer island capable of withstanding repetitive and excessive physical stress that can cause flexible and stretchable electronics to fail. The 3D-printed supporting material for tiny circuit boards can greatly increase the lifespan of flexible displays and stretchable skin-like sensors.

An island is a small, flat, and rigid panel that provides physical support for electrical components used in various stretchable devices. Islands are normally heat-melded or glued onto soft flexible skin-like materials. However, when the area around the island is constantly put under physical stresses such as folding and bending, the flexible material around the island will crack and tear to cause malfunctions.

Stress-induced cracks have been the biggest problem for stretchable devices, especially flexible displays, because it is inevitable for such devices to break after repetitive folding and bending actions.

The Korea Advanced Institute of Science & Technology (KAIST) said in a statement on July 7 that its research team has developed a 3D-printed Ferris wheel-shaped island for flexible and stretchable devices. Because the island has legs that stretch out of the main part, it can better withstand forces created by various actions such as twisting and folding than ordinary rectangular and circular-shaped islands. The new polymer island can also bond to other polymer materials without any chemical bonding process.

KAIST researchers created a flexible display module by putting light-emitting diode (LED) chips and a button-type battery onto the Ferris wheel-shaped island. "In order to commercialize the Ferris wheel-shaped island, it is important to acquire high-durability characteristics of the device when it is exposed to harsh conditions created during everyday situations," KAIST researcher Steve Park said.

Copyright ⓒ Aju Press All rights reserved.

View more comments