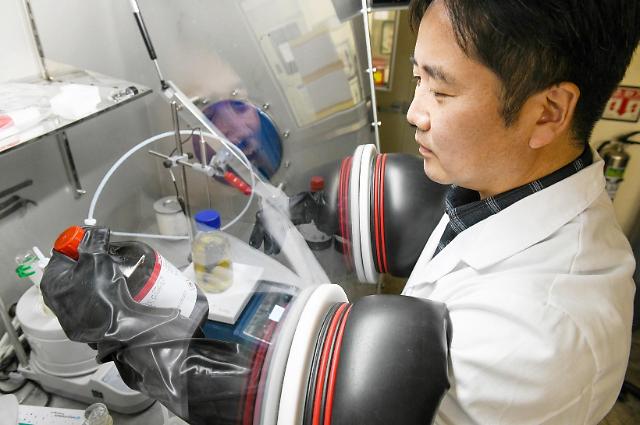

[Courtesy of Hyundai Motor]

SEOUL -- South Korea's Hyundai auto group partnered with Factorial Energy, a solid-state cell technology developer in the United States, to jointly develop new technologies for all-solid-state batteries which are seen as a next-generation power source for electric vehicles as solid electrolytes are nonflammable and more stable.

Solid-state batteries can have a higher energy density than lithium-ion batteries and enable faster charging, higher voltage and longer cycle life. Compared to flammable liquid electrolytes, solid-state batteries have a lower risk of catching fire. Fewer safety systems are needed, further increasing energy density.

The joint development agreement includes a strategic investment from the auto group, but financial terms were not disclosed. It marked Factorial's first major strategic investment from a major automotive group. The two companies would integrate Factorial's technology at the cell, module, and system levels

Factorial's solid electrolyte material is designed to enable safe and reliable cell performance with high-voltage and high-energy-density electrodes. "Our partnership with Hyundai is yet another validation of our solid-state battery technology, and we look forward to demonstrating its market readiness in Hyundai vehicles," Factorial CEO Siyu Huang said in a statement.

At a conference call on April 22, the Hyundai auto group vowed to seek the pilot production of electric vehicles installed with solid-state batteries in 2025 by securing a competitive edge in technology and manufacturing through strategic cooperation with domestic and foreign battery makers.

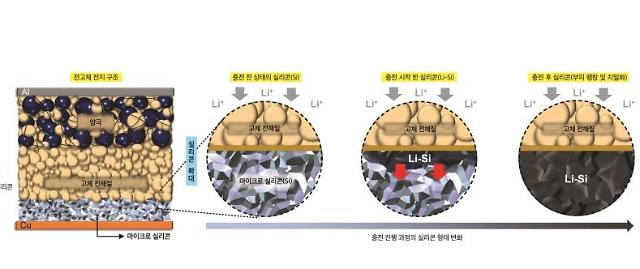

South Korean battery makers have tried to produce efficient and high-end batteries. In September, LG Energy Solution (LGES) claimed to have developed an all-solid-state battery with a long lifespan that can be charged at high speed even at room temperature, through a joint study with the University of California San Diego.

A month later, SK Innovation partnered with Solid Power of the United States to develop high-performance and commercially viable all-solid-state batteries. They would use nickel, cobalt, manganese (NCM) cathode materials and high-content silicon anode materials to produce all-solid-state batteries with high energy density.

Copyright ⓒ Aju Press All rights reserved.

View more comments