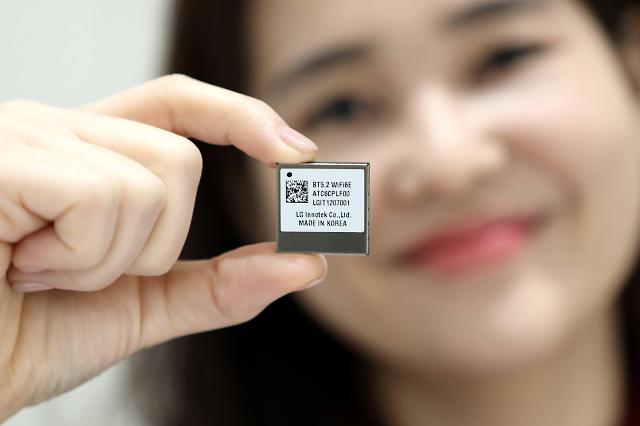

[Courtesy of LG Innotek]

Magnets are mounted on vehicle motors, smartphone cameras, audio speakers, and wind power generators. China has been a major source of rare earths, but rare-earth mining has caused severe water, air, and soil pollution, prompting Beijing to embark on a cleanup of polluted sites. Improving the performance of magnets while minimizing the usage of heavy rare earth metals has been a technically challenging task.

LG Innotek and Sunglim Group have developed a new magnet that reduced the use of heavy rare earth metals by 60 percent, compared to the previous one. The two companies aim to expand the application of their new product to air conditioners, refrigerators, drones, urban flying cars, and generators while developing magnets that do not contain heavy rare earth metals at all.

"It is meaningful that innovative technology has developed core materials in a short period of time to stably provide products with the best performance and quality to customers," LG Innoteck's Chief technology officer Kang Min-seok said in a statement on September 13. "We will continue to provide differentiated values to customers through eco-friendly magnets."

The new magnet can raise the performance of home appliances and vehicle steering motors to the world's highest level of 14.8 kilogaus (kG), LG Innotek said, adding that the reduced use of heavy rare earth metals can minimize the risk of production interruption to be caused by a lack of raw material supply, especially among automobile and parts makers.

LG Innotek said the new magnet is suitable for electric and hybrid vehicles that are in urgent need of lightweight to improve fuel efficiency. When mounted on cameras for high-definition smartphones, the eco-friendly magnet increases the actuator's driving force by about 10 percent to take clean and clear high-definition photos and videos.

New compounds were added to develop a coating solution that can produce the best magnetic force in various products and temperature ranges while using less heavy rare earth metals. LG Innotek and Sunglim have secured new magnet materials optimized for a coating solution. A machine learning simulation technique has shortened the development period.

Copyright ⓒ Aju Press All rights reserved.

View more comments