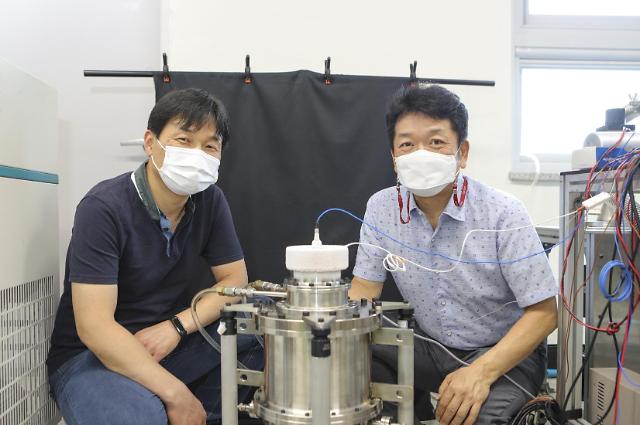

[Courtesy of KIMM]

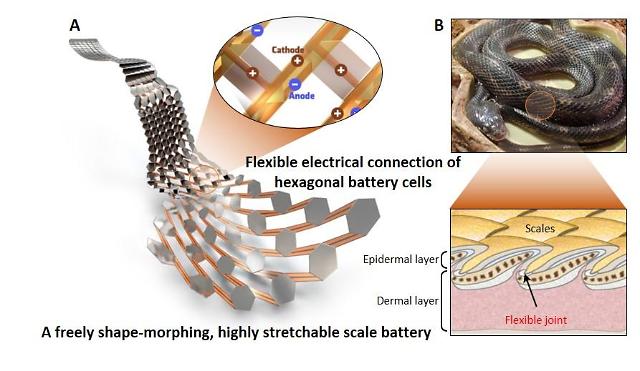

While traditional coolers are composed of multiple moving parts and use refrigerant gases that can accelerate global warming, a Stirling cooler, also known as a Stirling cryocooler, normally consists of very few moving parts, one or two pistons and a displacer. The cryocooler uses helium for maximum thermodynamic efficiency. Because a Stirling cooler has fewer parts, its size can be minimized to a size of an index finger.

A cold chain is a temperature-controlled supply chain. Fresh food ingredients, medicine and other products that need to be refrigerated use a network of cold chains for delivery and storage. The importance of an ultra-low cold chain was highlighted during the last few years as many vaccine vials for COVID-19 need to be stored or transported between -90 degrees Celsius (-130 Fahrenheit) and -60 degrees Celsius to manage the medicine's stability.

The Korea Institute of Machinery & Materials (KIMM) said in a statement on June 29 that its research team led by Dr. Park Seong-je has developed a Stirling cooler for ultra-low temperature freezers. "Ultra-low temperature Stirling coolers will set the stage for broadening potential applications of Stirling cooling technology and creating new industries," said Dr. Park.

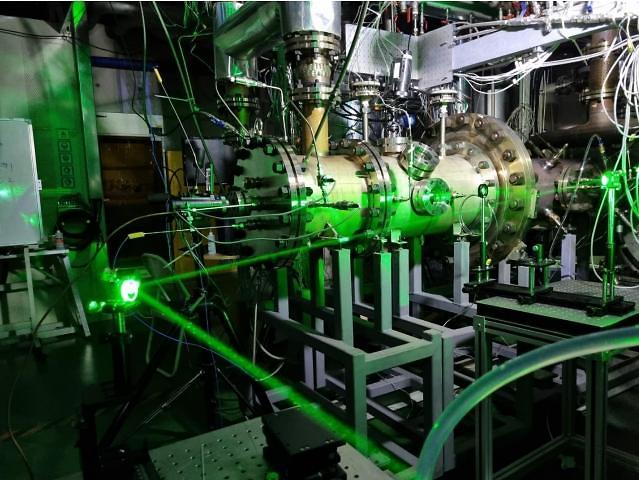

According to the institute, the new cryocooler technology is the brainchild of a research project that was kicked off 20 years ago. Through the Stirling cooler development project, researchers were able to develop coolers that can be attached to infrared sensors.

Copyright ⓒ Aju Press All rights reserved.

View more comments